Advantages

- Outstanding UV and weather resistance.

- Superior adhesion and flexibility.

- Moderate chemical resistance.

Application Methodology

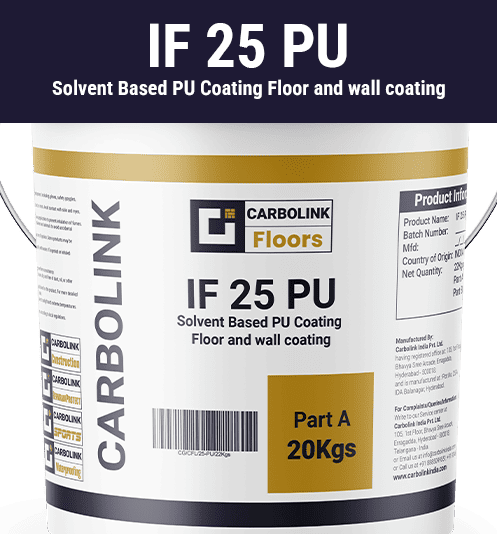

Ensure the surface is thoroughly cleaned using oil-free compressed air, sandblasting, wire brushes, or other mechanical methods to remove rust, oil, grease, dirt, and any other loose particles before applying the primer. IF 25 PU is applied as a topcoat over a suitable anticorrosive primer or intermediate coatings. For aged coatings, roughen the surface with emery paper grade 400/600 to enhance bonding. Apply the product only on dry surfaces. Stir Component A and Component B separately. If settling is observed in Component A, first loosen the material manually, then mix thoroughly using a power-driven stirrer to achieve a homogeneous consistency. Gradually add the hardener to the base while continuously stirring. After mixing, apply IF 25 PU using a brush, roller, conventional spray, or airless spray. Use a compatible thinner to achieve the desired workability, with thinner volume varying between 5-15% depending on the application method.

Physical Properties

| # | Technical Data | value |

|---|---|---|

| 1 | Pot Life at 30°C | 4.5 – 5 hours |

| 2 | Adhesion to Steel & Concrete | Excellent |

| 3 | Coverage | 6-8 m²/L at 75 μm |

| 4 | Drying Time at 30°C | Surface Dry: 30 minutes Hard Dry: 6 hours Full Cure: 7 days |

| 5 | Impact Resistance | >100 kg·cm |

| 6 | Hardness (Pendulum, after 7 days curing) | 195 seconds |

| 7 | Temperature Resistance | Up to 120°C |

| 8 | Weathering Resistance (QUV) | 1000 hours |

| 9 | Weathering Resistance (QUV) | 1000 hours |

| 10 | Finish | Glossy |

| 11 | Volume Solids | 50-60% |

| 12 | DFT (Dry Film Thickness) | 60-75 μm |

| 13 | Recoat Time | Minimum: 6 hours Maximum: 48 hours |

| 14 | Abrasion Resistance | 40 mg |

| 15 | Flexibility (Conical Mandrel) | < 1 mm |

| 16 | Application Temperature | 10°C to 40°C |

| 17 | Flash Point | >23°C (Base and Hardener) |