Key Features

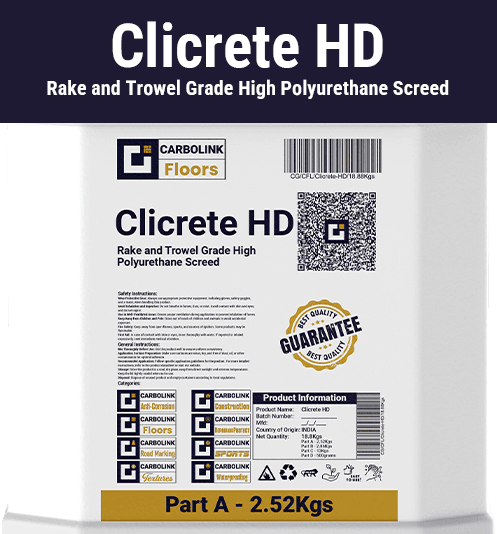

Easily applied by rake and trowel Hard wearing – extremely durable and abrasion resistant with low maintenance cost Facilitates rapid application Resistant to a wide range of chemicals and liquids Independently tested – suitable for use in food and drinks production environments Seamless – easily cleaned to maintain high standards of hygiene Resistant to thermal shock – at 9 mm thick can withstand steam cleaning regimes.

Application Guidelines

Surface Preparation The concrete or screed substrate must be hard, sound, and free of dust and other barrier materials such as paint, lime coatings, plaster, curing agents, laitance, adhesive residues, etc., that will inhibit adhesion to the substrate. Use a suitable degreaser to remove polish, wax, grease, oil, and similar contaminating substances before mechanical preparation. Contaminated concrete surfaces should be mechanically prepared, either by scabbling, grinding, or contained shot blasting equipment or similar, and be vacuumed clean before applying Clicrete HD. Overwatered or otherwise weak concrete surfaces must also be suitably prepared down to sound, solid concrete by mechanical methods. Dust and other debris should be removed using vacuum equipment.

Technical Specifications

| # | characteristic | value |

|---|---|---|

| 1 | Pot life | 20 mins |

| 2 | Light traffic | 24 hours |

| 3 | Full traffic | 48 hours |

| 4 | Full cure | 7 days |

| 5 | Bond strength | >1.5N/mm2 |

| 6 | Compressive strength | 53 N/mm2 |

| 7 | Flexural strength | 12 N/mm2 |

| 8 | Tensile strength | 7 N/mm2 |

| 9 | Shore D Hardness | 75 |

| 10 | Abrasion resistance | Classified ‘Special Duty’ under BS 8204: Part 2: 2002(9) |

| 11 | Slip resistance | Classified ‘Satisfactory’ under BS 8204: Part 2: 2002(9), wet and dry |

| 12 | Impact resistance | Classified ‘High Impact Resistance’ under BS 8204: Part 1: 1999 |

| 13 | Mixing Ratio | As specified on the container |