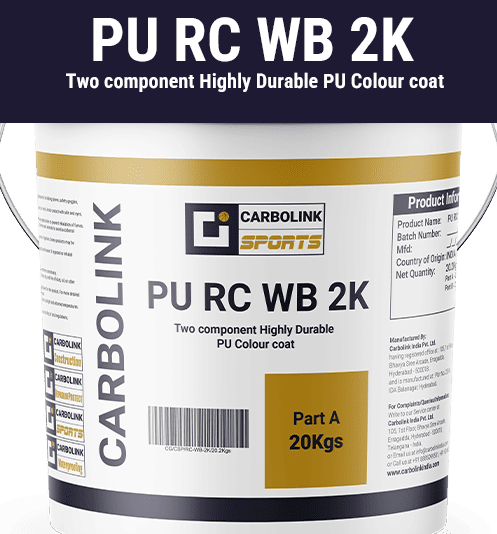

Features & Benefits

- Scratch Resistant

- Non-Yellowing & UV Resistant Topcoat

- Anti-Carbonation Protection

- Direct-to-Metal* and Concrete Application

- Chemical and Acid Resistant

- Excellent Protective Floor Coating

- Breathable Elastomeric Waterproofer

Surface Preparation

Ensure all surfaces are clean and dry, free from oils, dirt, debris, or minerals like efflorescence, lime, and calcium. These contaminants can prevent proper penetration and sealing of PU RC WB 2K. Use PU RC WB 2K Concrete and Masonry Cleaner system as a pretreatment for cleaning masonry surfaces. Allow surfaces to dry before sealing or fully applying a topcoat.

Technical Data

| # | Characteristic | Value |

|---|---|---|

| 1 | Solid by Weight (%) | Clear/Matte 35±(2%), Pigmented 40±(5%) |

| 2 | Solid by Volume (%) | 50% |

| 3 | Dry Time | 1 – 2 hours |

| 4 | Cure Time | 3 – 7 days |

Test Data

| 1 | Flash Point | >118°C (245°F) (Tag closed cup) |

|---|---|---|

| 2 | pH | Part A – N/A, Part B – 9.2 |

| 3 | Specific Gravity | 1.05 |

| 4 | Gloss | >90 @ 16°C (60°F) (Gloss meter) |

| 5 | Gloss Loss | < 10% (ASTM D523) |

| 6 | Color Loss | < 1.1% (ASTM D2244) |

| 7 | Salt Spray | 1500+ hours (ASTM B117) |

| 8 | Humidity | 1500+ hours (ASTM D2244) |

| 9 | Abrasion | <40 mg (ASTM D4060) |

| 10 | Hardness | >2H (ASTM D3363) |

| 11 | Adhesion | Pass (ASTM D2197) |

| 12 | Flexibility | Pass (ASTM D2794) |

| 13 | Surface Burning | Flame spread 0, Smoke development 0 (ASTM E84) |

| 14 | Odor | None |

| 15 | VOC (g/L, less water) | 0 |

| 16 | MEK Double Rub | Passed 2,000 cycles @ 50% solids |