Application Instructions

Surface Preparation

Ensure the surface is clean, structurally sound, and free from oil, grease, wax, polish, laitance, dust, and other barrier materials. All holes and cracks should be filled with a suitable filler material.

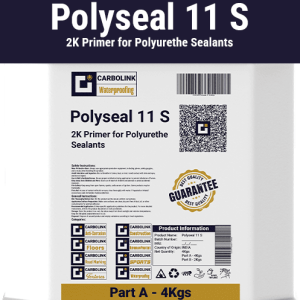

Priming

Apply a suitable primer to the surface to ensure proper adhesion of the membrane. Allow the primer to dry for at least 2 hours before applying the PRO MEMBRANE.

Application

1. Apply the Base Coat: Apply a generous base coat of primer waterproofing compound by brush or roller at a spread rate of 1 litre/m².

2. Embed the Membrane: Embed the PRO MEMBRANE into the base coat while it is still wet. Ensure the membrane is thoroughly embedded and smooth out all air pockets and creases. Overlaps of adjacent membranes must be a minimum of 50 mm.

3. Second Coat: Immediately apply a second coat of the waterproofing compound at a spread rate of 0.6 litre/m² while the base coat is still wet to fully saturate the membrane from both sides.

4. Final Top Coat: When touch-dry, apply a final top coat at a spread rate of 0.5 litre/m² to complete the application. Protect from rain until dry. Apply in 2 coats at an approximate wet film thickness of 0.3 mm per coat to achieve an overall dry film thickness of 0.3 mm. Allow the first coat to completely dry before applying the second coat.

Product Technical Data

| # | Characteristic | Value |

|---|---|---|

| 1 | Weight per unit area | 280 gr/m² (EN 1849-2) |

| 2 | Thickness | 0.04 mm (EN 1849-2) |

| 3 | Reaction to fire | Class F (EN 13501-1) |

| 4 | Water resistance | Class W1 (EN 1928) |

| 5 | Property of propagating water vapor (sd) | 83 mm (EN 12572) |

| 6 | Maximum tensile strength (MD) | 87 N/15mm (DIN EN ISO 527-3) |

| 7 | Maximum elongation by tension (MD) | 80% (DIN EN ISO 527-3) |

| 8 | Maximum tensile strength (CD) | 43 N/15mm (DIN EN ISO 527-3) |

| 9 | Maximum elongation by tension (CD) | 110% (DIN EN ISO 527-3) |

| 9 | Air pressure | 3 Bar |

| 10 | Water resistance | 1.5 Bar (DIN EN 1928) |