Key Features

- Transparent, low-shrinkage casting with tack-free surfaces

- Very good flow properties (low-viscosity)

- Cold-hardening, demouldable at room temperature, applicable at slightly increased temperatures

- Highly fillable casting resin

- Pressure-resistant and impact-resistant (tough) molds/components with high strength and minimal shrinkage

Recommended Uses

Industrial modeling / hobby modeling / boatbuilding

Ideal for “River Table” making

Creation of transparent, water-clear castings

Foundry patterns, die plates, reproduction patterns, building of medium molds and castings

Use as an injection system for repairs

Encapsulation of decorative elements

Levelling compound / injection resin for structural repairs

Application Guidelines

For better UV resistance, apply a suitable PU-Based clear coat (e.g., HP-PUR). During the hardening process, energy may be released as heat; therefore, cooling/heat exchange should be provided to prevent hot spots.

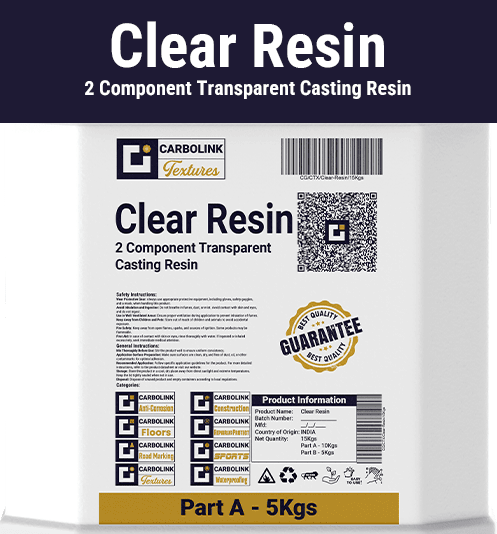

Technical Specifications

| # | Characteristic | Value |

|---|---|---|

| 1 | Coloring | Colorless (resin), slightly yellowish (hardener) |

| 2 | Mixing Ratio | 100 parts resin : 50 parts hardener (by weight) |

| 3 | Mixed Viscosity | Low-viscous |

| 4 | Working Time (Pot Life) | >60 minutes at 20°C |

| 5 | Demouldable After | <48 hours at 20°C, <24 hours at 30°C |

| 6 | Full Cure | 7 days at 20°C |

| 7 | Working Temperature | 18-35°C |