Properties

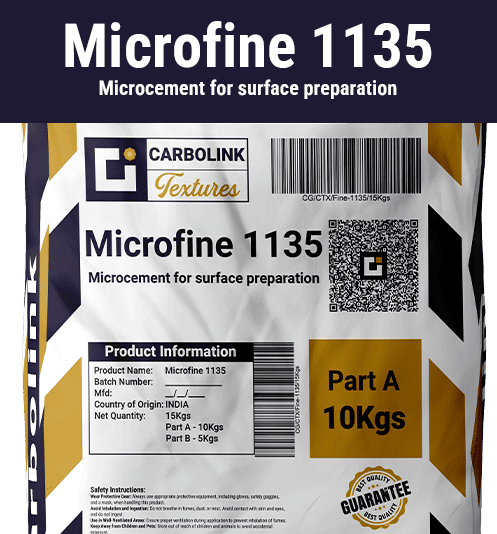

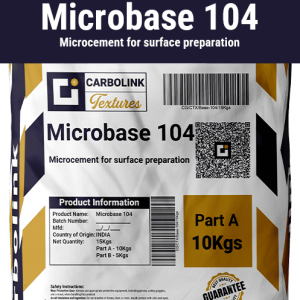

CCLI MicroFine 1135 offers a continuous decorative coating without fissures, provided that expansion joints are respected. It is applicable on numerous surfaces, including concrete, cement, ceramic, plasterboard, and more. The product has excellent workability and is available in a wide range of colors with finishes such as matt, satin, and gloss. It also provides high adhesion to substrates.

Recommendations for Use

Surface preparation: Prior to application, it is necessary to prepare the surface according to the conditions of the substrate to be coated. Some coatings may require specific solutions such as the flat and flexible fiberglass mesh Builtex. Mix: Add resin and pigments in the recommended proportions. It is essential to respect the resin-microcement ratio to ensure the product’s properties. For example, mix 10 kg of CLI MicroFine 1135 with 3.0 liters of resin. Mortar preparation: The mortar must be prepared by pouring some Part A into a container, adding the entire load of pigment corresponding to the amount of microcement, and mixing until an even, colored liquid is obtained. Gradually pour the microcement powder into the resin while mixing the product with a low-speed mixing drill for at least 4 minutes until a smooth mixture free of lumps is obtained. Consumption: Consumption depends on the surface. In a standard application, CLI MicroFine 1135 (2 layers) requires approximately 1.40 kg/m². Better leveling and preparation of the surface to be coated can lead to lower consumption and reduced installation time.

Technical Data

| # | Characteristic | Value |

|---|---|---|

| 1 | Type | Two-component microcement |

| 2 | Appearance | White powder |

| 3 | Maximum Size of the Aggregates | 0.135 mm |

| 4 | Apparent density (in powder) | 1175 ± 50 kg/m³ |

| 5 | Apparent density (in mortar) | 1480 ± 50 kg/m³ |

| 6 | Apparent density (hardened, 28 days) | 1430 ± 50 kg/m³ |

| 7 | Compressive strength (EN 13892-2, 28 days) | ≥ 55 N/mm² |

| 8 | Flexural strength (EN 13892-2, 28 days) | ≥ 10 N/mm² |

| 9 | Adherence strength (EN 13892-8, 28 days) | ≥ 1.5 N/mm² |

| 10 | Fire resistance (EN 13501-1) | BFL s1 |

Application

Application layers: Apply one or two layers of CLI MicroFine 1135 with a steel trowel depending on the type of surface. On floors, always apply two layers and use the flexible fiberglass mesh Builtex. Before applying a new layer, sand the previous one with a random orbital sander and 40-grit sandpaper to remove irregularities. Finishing or setting coat: The application can be finished with a third coat of CLI MicroFine 1135 using the “fresh on fresh” technique. CLI MicroFine 1135 can be installed onto floors in two layers both on floors and walls. Do not apply layers thicker than 1 mm. A total thickness of the combined layers should not exceed 3 mm. Sealing: CLI Micro Topping should be sealed once it has hardened, after 24-48 hours. Sealing should be done after the coating reaches humidity lower than 5%, measured with tools designed for this purpose. CLI Micro Topping can be sealed with the primer Microseal A/P(U)/P(2S). It is highly recommended to follow the application instructions of the technical datasheet carefully.