Recommended Uses

Prior to applying CLI Microbase 105, the surface must be properly prepared depending on its condition. Specific coatings may require solutions like flat and flexible fiberglass mesh Builtex. The surface should be free of dust and grease, well-consolidated, and level.

Properties

Continuous decorative coating without fissures (always respect the expansion joints). Applicable on countless surfaces, including concrete, cement, ceramic, plasterboard, and more. Excellent workability. Wide range of colors. Finishes include matt, satin, and gloss. High adhesion to substrates.

Recommendations for Use

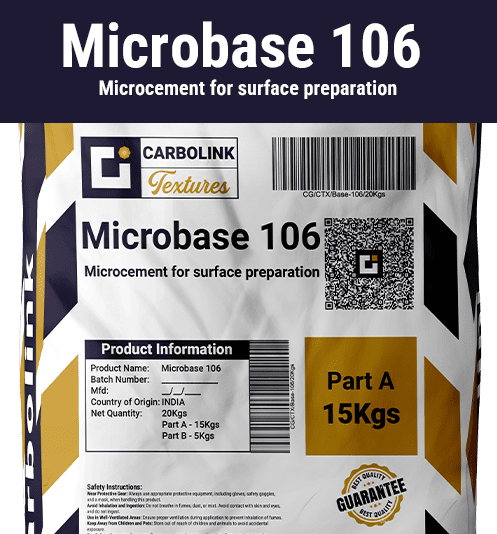

CSurface Preparation: Prior to the application of CLI Microbase 106, it is necessary to prepare the surface depending on the conditions of the support to be coated. Some coatings require specific solutions like the flat and flexible fiberglass mesh. Mix: Add CLI Micro Topping resin and pigments in the recommended proportions. It is essential to respect the resin-microcement ratio to ensure the product’s properties: 10 kg of CLI Microbase 106 with 2.5 – 3.0 liters of CLI Micro Topping resin. Mortar Preparation: The mortar must be prepared as follows:

1.Pour some Part A into a container, then add the entire load of pigment corresponding to the amount of microcement and mix until an even, colored liquid is obtained.2.Pour the microcement powder gradually into the resin while mixing the product with a low-speed mixing drill.

3.Mix for at least 4 minutes until a smooth mixture free of lumps is obtained. Consumption: The consumption depends on the surface. In a standard application, it would be as follows: CLI Microbase 106 (2 layers) – 2.00 kg/m2. The better the leveling and preparation of the surface to be coated, the better the consumption and the lower the time of installation. It is advisable to choose the suitable method for each application.

Technical Data

| # | Characteristic | Value |

|---|---|---|

| 1 | Type | Two-component microcement |

| 2 | Appearance | White powder |

| 3 | Maximum Size of the Aggregates | 0.5 mm |

| 4 | Apparent Density | In powder – 1175 ± 50 kg/m3; In mortar – 1480 ± 50 kg/m3; Hardened – 1430 ± 50 kg/m3 (28 days) |

| 5 | Compressive Strength (EN 13892-2) | 28 days: ≥ 55 N/mm2 |

| 6 | Flexural Strength (EN 13892-2) | 28 days: ≥ 10 N/mm2 |

| 7 | Adherence Strength (EN 13892-8) | 28 days: ≥ 1.5 N/mm2 |

| 8 | Fire Resistance (EN 13501-1) | BFL s1 |