Key Features

Hard wearing – extremely durable and abrasion resistant with low maintenance costs Resistant to a wide range of chemicals and liquids Seamless – easily cleaned to maintain high standards of hygiene.

Recommended Uses

Factories General heavy duty plant areas Traffic areas.

Application

For flooring applications, the mixed material should be applied to the prepared and primed surface between 8 and 24 hours after priming, using a trowel to achieve the desired thickness. As soon as the product has been laid and as work progresses, the surface should be gently rolled with a spiked roller in order to provide an even surface appearance. Do not re-roll later. The work area should be protected during the installation process and during the initial curing time to ensure that no airborne debris can contaminate the surface of the wet resin as this will lead to unwanted blemishes in the hardened, cured surface. All movement joints in the sub-floor must be carried through the topping and properly sealed. Construction joints and cracks not subject to movement may be overlaid but should the floor move in any way, these defects will reflect through the system. Isolation joints will need to be allowed for in areas where high thermal movement is anticipated, e.g., around ovens and freezers.

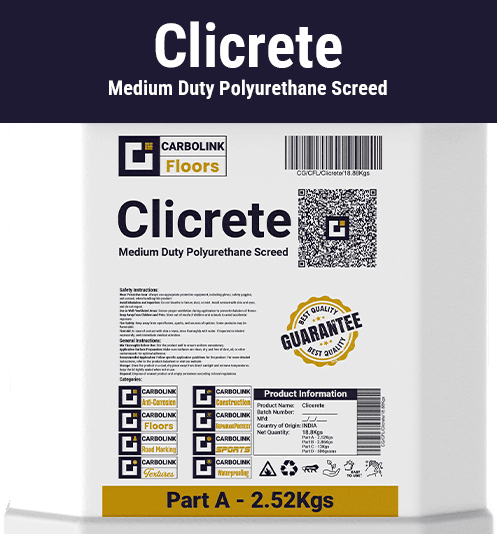

Physical PropertiesClicrete @27±1°C

| # | characteristic | value |

|---|---|---|

| 1 | Pot life | 20 mins |

| 2 | Light traffic | 24 hours |

| 3 | Full traffic | 48 hours |

| 4 | Full cure | 7 days |

| 5 | Bond strength | >1.5N/mm2 |

| 6 | Compressive strength | 51 N/mm2 DIN EN ISO 604 |

| 7 | Flexural strength | 18 N/mm2 DIN EN ISO 178 |

| 8 | Tensile strength | 7 N/mm2 DIN EN ISO 527 |

| 9 | Shore D Hardness | 75 |

| 10 | Abrasion resistance | Classified ‘Special Duty’ under BS 8204: Part 2: 2002(9) |

| 11 | Slip resistance | Classified ‘Satisfactory’ under BS 8204: Part 2: 2002(9), wet and dry |

| 12 | Impact resistance | Classified ‘High Impact Resistance’ under BS 8204: Part 1: 1999 |