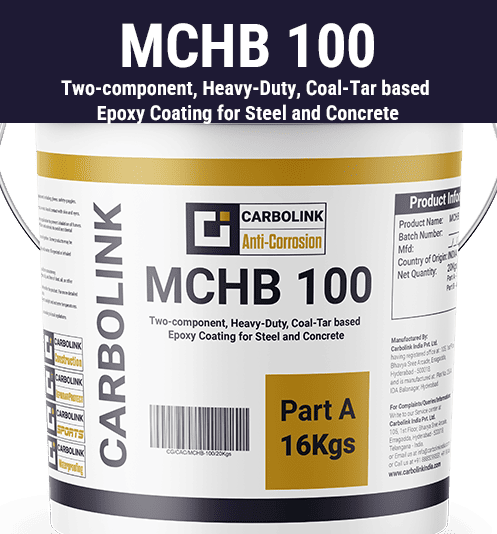

Advantages

Low viscosity formulation helps in easy application by brush or spray. Flexible anti-corrosive/preventive coating for structures – MS or concrete – even where the structure is in continuous contact with water or submerged. Provides excellent resistance to corrosion, impact, thermal shock and abrasion. Cures to a hard, smooth, and flexible surface with excellent resistance to sea/salt water, oil, acids, alkalis, crude oil, and minerals. Compatible with cathodic protection.

Application Information

Substrate Temperature: +10℃ Min / +40C Max

Ambient Temperature: +10C Min / +40°C

Max Substrate Moisture Content: <5%

Application Methodology

Surface Preparation: Clean the surface using a metal brush or shot blasting to remove rust, oil, and other contaminants. Mixing: Stir each component separately using a hand drill-type stirrer before mixing them together. Allow the mixture to sit for 5 minutes before application to allow any air bubbles to subside. Application: Apply MCHB 101 with a brush or spray. For spray applications, a plural spray system is recommended.

Surface Preparation Steel

Blast cleaned to ISO-Sa22 and remove dust, flakes, oil, grease or other loose foreign particles. Application of MCHB 100 should be straight after steel preparation to prevent surface rusting. In case of new concrete, ensure the concrete is at least 28 days old and remove any loose foreign particles by compressed air. Ensure the ambient temperature is not less than 10°C and not more than 40C at the time of coating. To avoid condensation of moisture onto the coating substrate prior to application, RH should not be above 80% and substrate temperature should be at least more than 3C above Dew point.

Material Preparation

Stir drums of each component of MCHB 100 thoroughly to a homogenous and uniform mix with a slow speed stirrer fitted with a suitable mixing paddle.Component A and B in a suitably sized container. Mix properly for 3-5 minutes with a slow speed stirrer until a homogeneous color is achieved. Keep the paddle below the surface to avoid entrapping air. Do not mix by hand. The temperature of the mixed base and hardener should preferably be more than 12C, otherwise extra thinner may be required to obtain application viscosity. Thinner addition results in reduced sag resistance, volume solid, and DFT. Apply the material as supplied, do not dilute with thinner.

Technical Characteristics at 28C, 50% RH