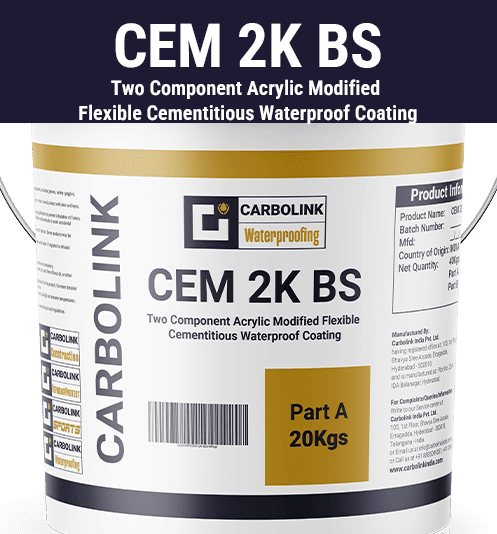

CEM 2K BS

Two Component Acrylic Modified Flexible Cementitious Waterproof Coating

CEM 2K BS is a versatile two-component, cementitious waterproofing compound formulated with advanced acrylic polymer technology. It is designed for use in areas where substrates are subjected to movement and require crack-bridging properties. This coating offers superior flexibility and water resistance, making it ideal for various waterproofing applications.

Guaranteed Reliability

We design our materials for exceptional lifespan and unwavering reliability.

Unbeatable Value

Exceptional Performance at an Outstanding Price

Certified Quality

Meeting Industry Standards for Performance and Safety