Recommended Uses

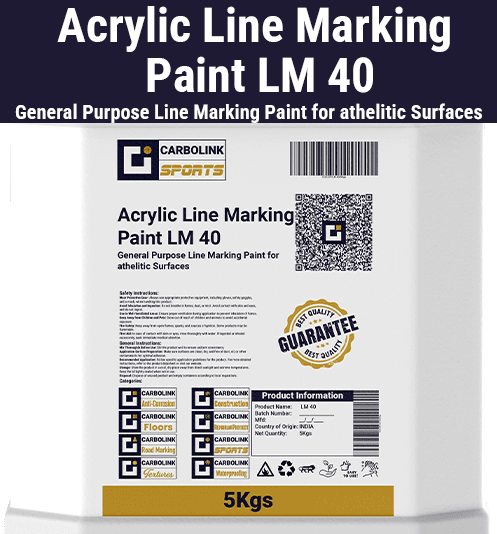

Acrylic Line Marking Paint LM 40 is ideal for striping color-coated recreational surfaces or any asphalt or concrete surface in light traffic

areas, such as tennis courts, play areas, curbs, berms, and parking lots.

Application Guidelines

Surface Preparation

one to two applications provide excellent coverage.

Application

Apply LM 40 Paint to a clean, dry, color-coated surface using a brush, roller, airless spray, or specialized marking equipment..

Guide Instructions

System Recommendation

Substrate Cure Requirements: New hot-mix asphalt surfaces require at least 14 days of curing before applying LM 40 Paint. New

Portland cement concrete surfaces need a minimum of 28 days curing.Surface Condition: Ensure the surface is smooth and free of dirt, loose or flaking paint, oily materials, chemical residues, vegetation,

and other debris that could prevent proper adhesion.Mixing Instruction:

LM 40 paint is ready to apply. Only gently stirring in necessary. Do not dilute.

Mixing Instructions

Sand Mix: Use clean sand free of clay, silt, ferrous metals, or salt. Add sand slowly to undiluted Acrylic Color Kote T-50, followed by

water. Stir the mixture until homogeneous using a mechanical mixer. Stir periodically during application to ensure consistency. Water Mix: The maximum dilution ratio is 2 parts Acrylic Color Kote T-50 to 1 part water for texture courses and 3 parts Acrylic Color

Kote T-50 to 2 parts water for finish courses

Guide Instructions

System Recommendation

one to two applications provide excellent coverage.

Application

Apply LM 40 Paint to a clean, dry, color-coated surface using a brush, roller, airless spray, or specialized marking equipment.

Drying and Cure Time

Allow LM 40 Paint to dry for 4 hours between coating applications. Completed projects should cure for at least 24 hours before use.