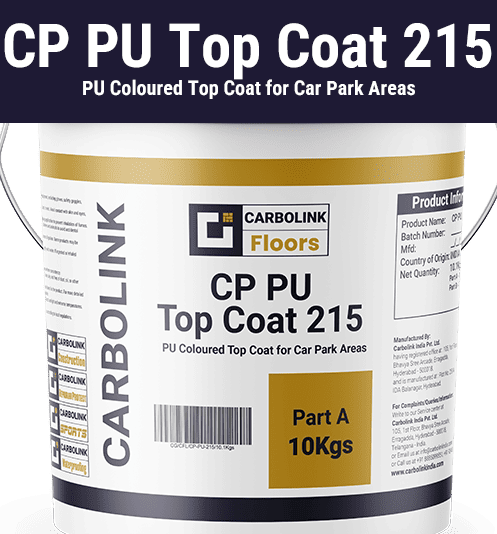

CP PU Top Coat 215

PU Coloured Top Coat for Car Park Areas

PU Top Coat 215 is a high-performance, water-based, two-component polyurethane coating for car parks. It offers superior durability, zero VOC emissions, UV resistance, and breathable waterproofing. Easy to apply by spray, brush, or roller, it withstands harsh weather, corrosion, and abrasion while remaining environmentally safe.

Guaranteed Reliability

We design our materials for exceptional lifespan and unwavering reliability.

Unbeatable Value

Exceptional Performance at an Outstanding Price

Certified Quality

Meeting Industry Standards for Performance and Safety