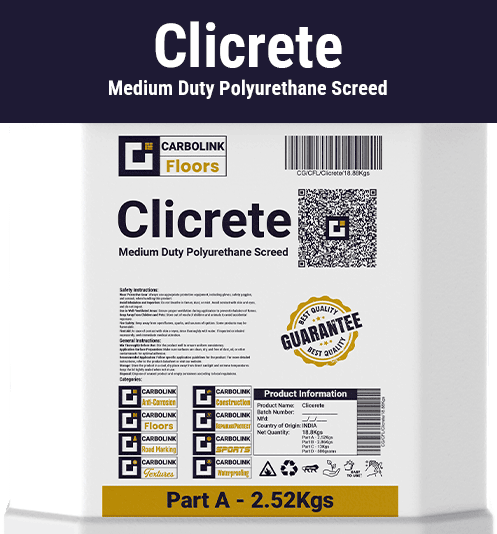

Clicrete

Medium Duty Polyurethane Screed

Clicrete is a medium duty polyurethane screed, specifically designed for flooring applications in aggressive environments. It combines outstanding wearing properties with high chemical resistance and is ideal for areas requiring a seamless, joint-free finish for maximum cleanliness.

Guaranteed Reliability

We design our materials for exceptional lifespan and unwavering reliability.

Unbeatable Value

Exceptional Performance at an Outstanding Price

Certified Quality

Meeting Industry Standards for Performance and Safety