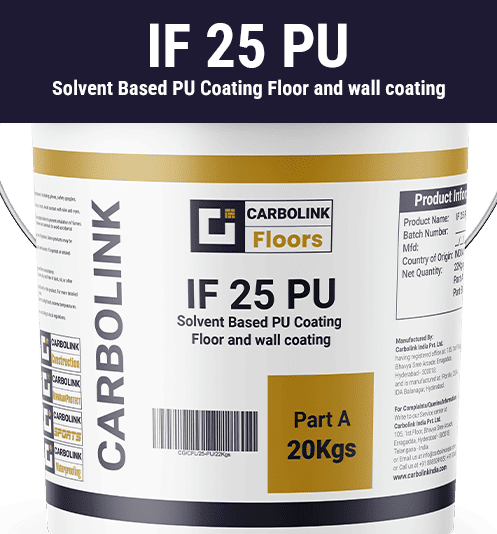

IF 25 PU

Solvent Based PU Coating Floor and wall coating

IF 25 PU is a two-component aliphatic polyurethane coating designed to offer exceptional UV and weather resistance. It is an ideal protective coating for exposed surfaces, providing excellent durability and stability under light and weathering conditions.

Guaranteed Reliability

We design our materials for exceptional lifespan and unwavering reliability.

Unbeatable Value

Exceptional Performance at an Outstanding Price

Certified Quality

Meeting Industry Standards for Performance and Safety