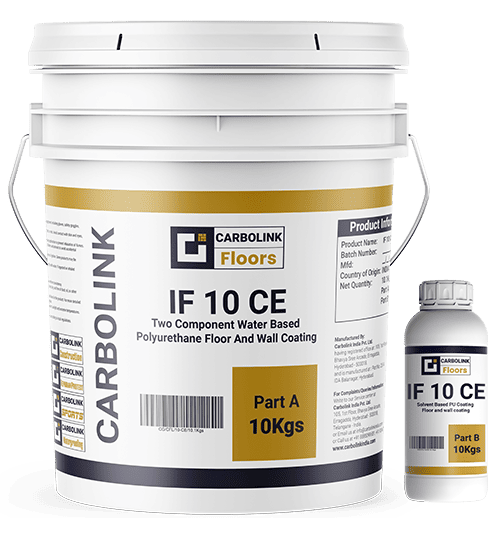

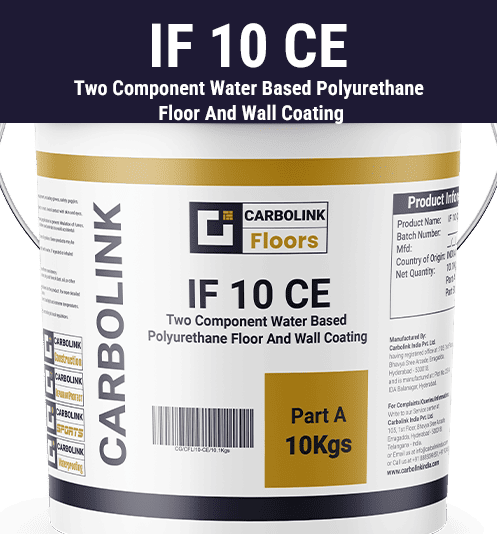

IF 10 CE

Two Component Water Based Polyurethane Floor And Wall Coating

IF 10 CE is a two-component water-based polyurethane floor and wall coating. IF 10 CE can be extensively used for applications where a thin coating is required to reduce texture or improve appearance and cleaning. IF 10 CE is also suitable for application on previously applied epoxy and polyurethane floors and walls.

Guaranteed Reliability

We design our materials for exceptional lifespan and unwavering reliability.

Unbeatable Value

Exceptional Performance at an Outstanding Price

Certified Quality

Meeting Industry Standards for Performance and Safety