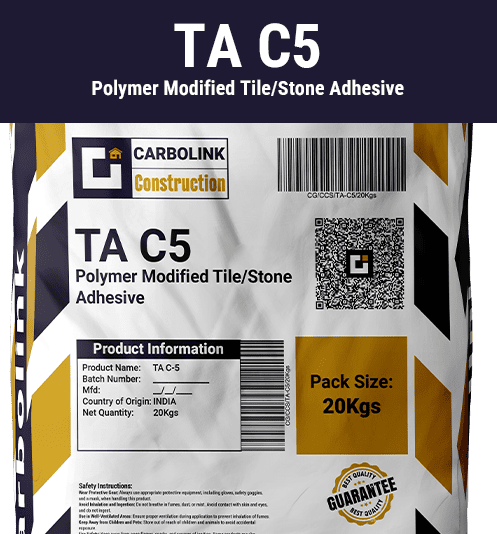

TA C5

Polymer Modified Tile/Stone Adhesive

High polymer modified, white cement-based tile adhesive suitable for fixing medium format tile/stone in interior walls/floor and exterior floor situations up to 6mm bed thickness (can be extended up to 12mm in areas of limited extent). The set adhesive is water-resistant and is suitable for use in showers and totally immersed situations such as swimming pools.

Guaranteed Reliability

We design our materials for exceptional lifespan and unwavering reliability.

Unbeatable Value

Exceptional Performance at an Outstanding Price

Certified Quality

Meeting Industry Standards for Performance and Safety