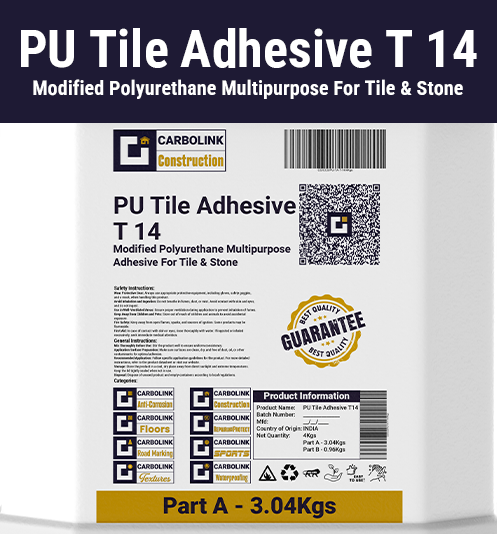

PU Tile Adhesive T 14

Modified Polyurethane Multipurpose For Tile & Stone

PU Tile Adhesive T 14 is a two-part modified polyurethane multipurpose adhesive designed for fixing all types of tiles and stones on a variety of substrates in both interior and exterior areas, whether on walls or floors. It is specifically formulated for fixing water-sensitive tiles and stones on deformable or absorbent/non-absorbent substrates.

Guaranteed Reliability

We design our materials for exceptional lifespan and unwavering reliability.

Unbeatable Value

Exceptional Performance at an Outstanding Price

Certified Quality

Meeting Industry Standards for Performance and Safety