Application Methodology

Apply the homogeneous two-component thoroughly stirred mixture to the cleaned, evened, and bone-dry surface @ 5-6 m2/L. Lay the mix on a bone-dry surface at temperatures ranging between 10°C to 50°C using a brush or roller. Install Prime Zn 30 by spreading evenly over the recommended area. Avoid excess application and mixing. Do not apply Prime Zn 30 in more than 50 microns DFT in a single coat. Apply the second coat of Prime Zn 30 on the bone-dry first coat. Prime Zn 30 may be over-coated with conventional paints or two-pack epoxy paints/Polyurethane paints. Over-coating can be done after 6 - 8 hours; however, it is recommended to coat after 12 - 24 hours of application of primer to obtain superior performance.

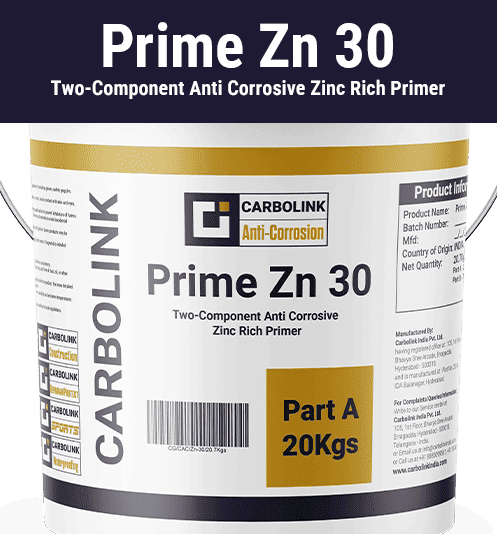

Packaging and Storage

Prime Zn 30 should be stored in a dry and cool place, protected from direct sunlight. Use within the shelf life period for the best results.

Technical Specifications

#

Characteristic

Value

1

Pot Life

10-15 minutes

2

Dry Time

1.5 hours

3

Dry Film Thickness

35 microns

4

Specific Gravity

1.50 + 0.02

5

Theoretical Coverage

5-6 m2/L

6

Minimum Application Temperature

10°C - 50°C

7

Mixing Ratio

100:3.5 by weight

Data Reliability

All technical data provided in this document are based on laboratory tests. Actual performance may vary due to factors beyond our control.

Regional Compliance

Product specifications may vary based on local regulations. Please refer to the local Product Data Sheet for precise information.

Legal Disclaimer

The information and recommendations regarding the application and end-use of Carbolink products are provided in good faith based on our current knowledge and experience. Due to variations in materials, substrates, and actual site conditions, no warranty of merchantability or fitness for a specific purpose can be inferred. The user must determine the product's suitability for the intended application. Carbolink reserves the right to change the properties of its products. All proprietary rights of third parties must be observed. Orders are subject to our current terms of sale and delivery. Always refer to the most recent local Product Data Sheet, available upon request.