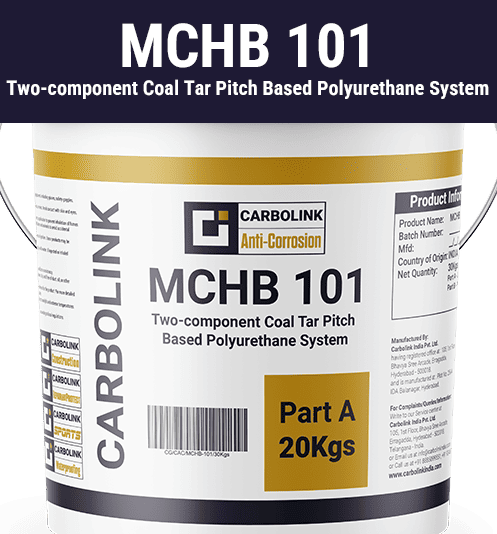

MCHB 101

Two-component Coal Tar Pitch Based Polyurethane System

MCHB 101 is a two-component polyurethane system that includes special coal tar pitch as a key ingredient. It is designed as an anticorrosive coating for steel pipelines, structures, and other steel and concrete surfaces that are exposed to severe salt corrosion.

Guaranteed Reliability

We design our materials for exceptional lifespan and unwavering reliability.

Unbeatable Value

Exceptional Performance at an Outstanding Price

Certified Quality

Meeting Industry Standards for Performance and Safety